Nanjing Ziyang New Material Technology Co., Ltd. was established on January 25, 2016, and is located in Nanjing Economic and Technological Development Zone, Jiangsu Province. Mainly engaged in processing, production and sales of nano thermal insulation materials and microcrystalline ceramic materials.

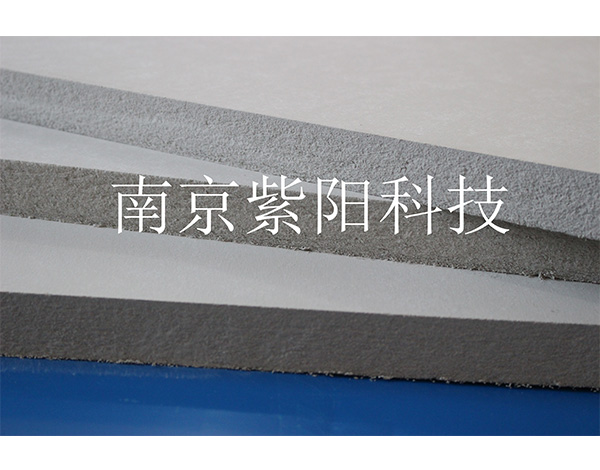

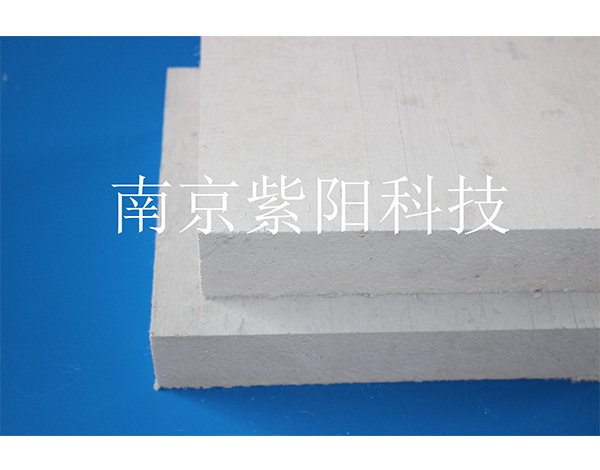

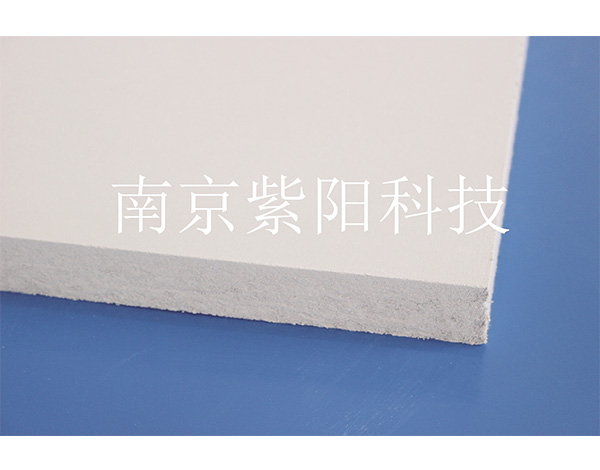

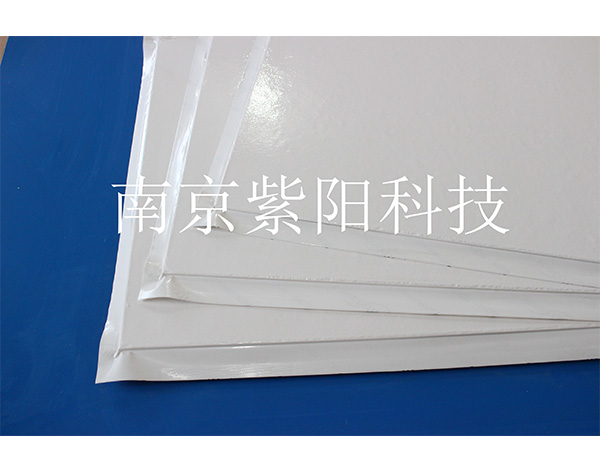

Our company adopts unique nanotechnology, and through a series of core special equipment developed with great concentration, we have successfully produced a new type of nano thermal insulation material. With its excellent performance, it has reached the advanced level of similar materials of the world's first-class manufacturers. The thermal conductivity of this product is smaller than that of static air, Its thermal insulation performance is 3 ~ 4 times better than that of traditional fiber thermal insulation materials, and it is one of the best refractory thermal insulation materials.

Our company's main product models are 950 type nano thermal insulation board, 1000 type nano thermal insulation board, 1200 type nano thermal insulation board, 1100 type nano thermal insulation felt, 1550 type microcrystalline board and 1550 type microcrystalline cylinder.

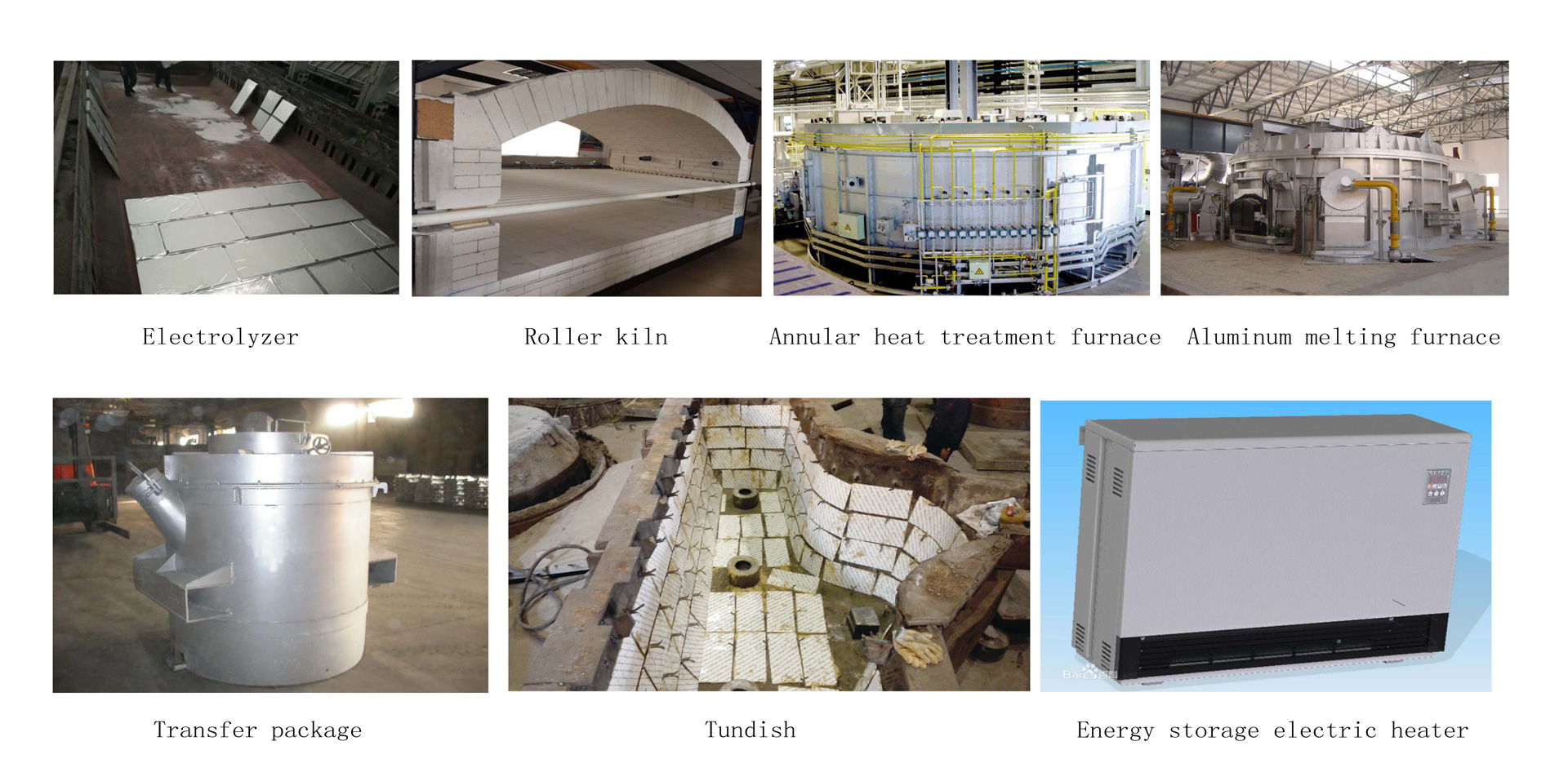

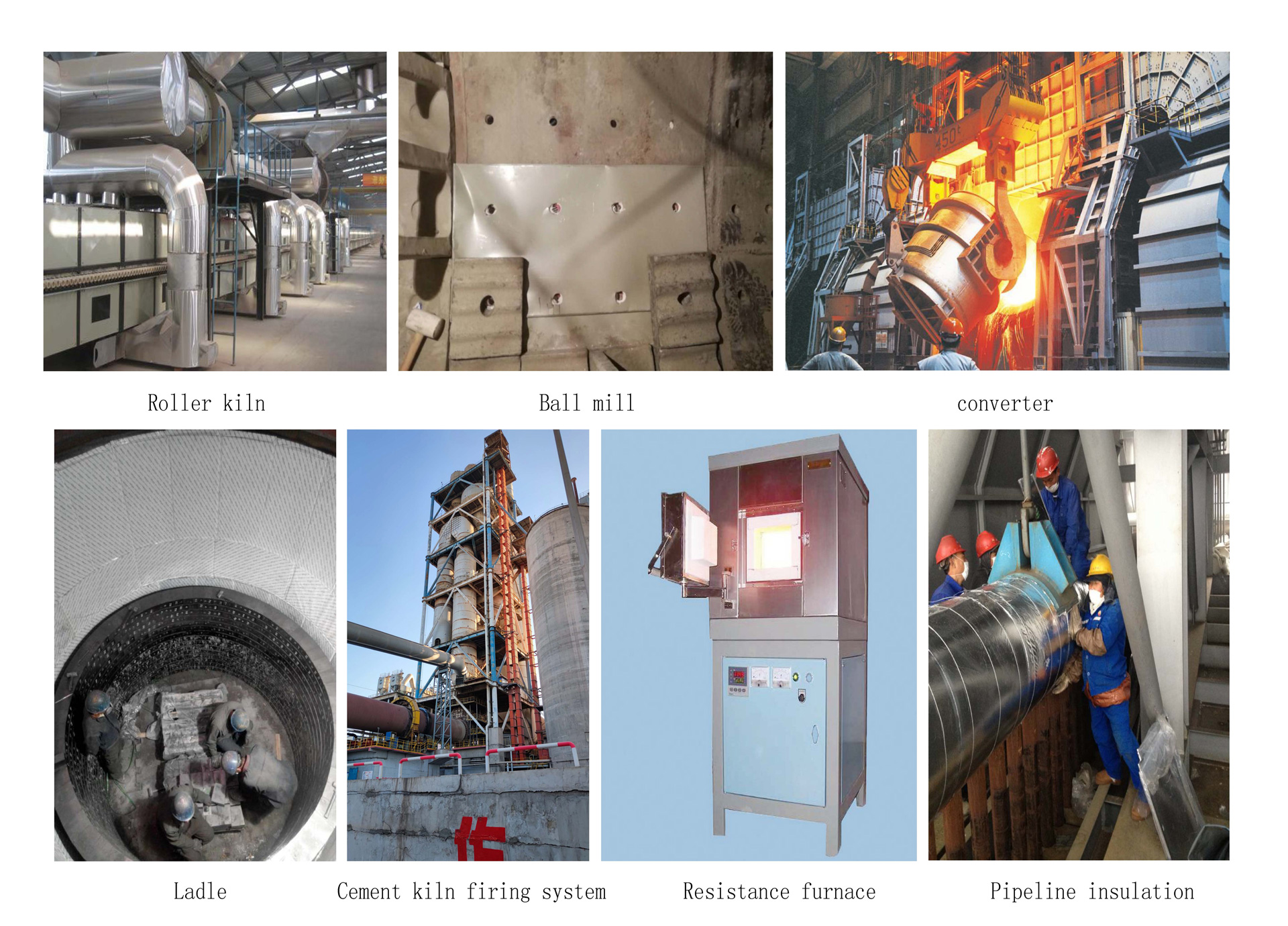

Nano thermal insulation materials can solve the problem of high temperature and overheating in cement industry, aluminum industry, steel industry, furnace industry and other fields, reduce heat loss, save coal consumption, and provide favorable conditions for enterprises to improve production efficiency and reduce operating costs. Microcrystalline ceramic materials can reduce clinker scaling, material deposition and operation cost for cement kiln firing system, and provide convenient conditions for cement enterprises to improve production efficiency.

As a new type of energy-saving and environment-friendly nano thermal insulation material, the product has great development potential and is widely used in various high-temperature industrial kilns, metallurgical industry, high-temperature pipeline, non-ferrous industry, cement thermal industry, household appliances and building fire prevention.

application area

Nanjing Ziyang New Material Technology Co., Ltd

官方微信