With the rapid development of China's cement industry, in recent years, cement plants gradually take capacity expansion and energy saving as important measures for the development of cement enterprises. It is understood that the firing system of the cement plant has been operating at high temperature for a long time. Choosing a better heat insulation material and lowering the shell temperature without increasing or even decreasing the insulation thickness can effectively expand the effective volume and reduce the heat loss, so as to reduce energy consumption and improve the economic benefits of the enterprise.

The zit nano thermal insulation material independently developed, produced and sold by Nanjing Ziyang New Material Technology Co., Ltd. is about 4 times better than the traditional calcium silicate board thermal insulation material in performance, which can achieve the purpose of expanding volume and saving energy.

Due to the super insulation properties of the zit nano insulation material, the shell temperature of the equipment can be significantly reduced and more energy can be saved under the same insulation thickness.

1、 Tertiary air duct of Qianshan Mountain, Liaoyang

Qianshan Mountain, Liaoyang is located in the northeast of China. It attaches great importance to the energy-saving transformation of the sintering system. The traditional heat preservation scheme can not meet their heat insulation needs. After technical exchange with our company, we adopted the thermal insulation scheme of 50 mm nano plate instead of 50 mM calcium silicate plate.

On March 5, 2019, the tertiary air duct of Qianshan Mountain, Liaoyang was installed with zit 1000 nano plate. The original 115mm calcium silicate plate was still used in the head and tail, and the composite insulation scheme of 50mm1000 nano plate and 65mm calcium silicate plate was used in the middle. On May 22, Qianshan cement technology department specially conducted the shell temperature contrast test, and the result showed that the shell temperature contrast decreased by 15 ~ 20 degrees, achieving the expected heat insulation effect. See TABLE-1 for details.

Effect table of air insulation transformation of tertiary air Duct-1

|

Serial number |

Structure of tertiary air duct |

Front end temperature (℃) |

Rear end temperature (℃) |

|

1 |

114 refractory brick + 115 calcium silicate board |

118 |

108 |

|

2 |

114 refractory brick + 50 nanometer plate + 65 calcium silicate plate |

99 |

92 |

|

3 |

Contrast cooling |

15~20 |

15~20 |

2、 Five stage cyclone and flue gas chamber of xingchuancheng Wangyang Jianbao cement company

The five stage cyclone and flue gas chamber of xingchuancheng Jianbao Cement Co., Ltd. have been retrofitted with nano thermal insulation materials. On March 26, 2019, the field engineer of the process department carried out the temperature measurement, and the results showed that the shell temperature was greatly reduced, and the cooling effect was remarkable. The detailed application effect comparison is shown in table-2 and table-3

Effect table of structural transformation of air inlet of five-stage cyclone tube - 2

|

Serial number |

Air inlet structure of five stage cyclone |

Original shell temperature (℃) |

remarks |

|

1 |

200 mm castable |

120~150 |

|

|

2 |

150 mm firebrick + 20 mm zit950 nano heat insulation board |

70~80 |

|

|

3 |

The thickness of refractory lining should be reduced by 30mm, the inlet resistance of cyclone should be reduced, and the shell temperature should be reduced by 50 ~ 70 ℃ |

||

Effect table of expansion and reconstruction of flue gas room - 3

|

Serial number |

Heat insulation structure of flue gas chamber |

Shell temperature (℃) |

remarks |

|

1 |

300 mm castable + 50 mM calcium silicate board |

150~200 |

|

|

2 |

250 mm firebrick + 20 mm zit950 nano heat insulation board |

100~120 |

|

|

3 |

The thickness of refractory lining is reduced by 80mm, the resistance of flue gas chamber is reduced, and the shell temperature is reduced by 50 ~ 80 ℃ |

||

3、 Laishui Jidong Cement Mill

Due to the high temperature heat transfer of clinker, the temperature of sliding shoe after cement grinding is relatively high. Especially in summer, the temperature of sliding shoe often exceeds the alarm temperature, which seriously affects the normal production.

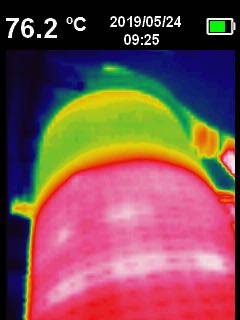

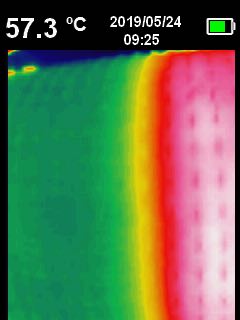

After investigation and comparison, under the lining plate near the thick sliding shoes, the shell temperature of the cylinder is reduced from 76 ℃ to 57 ℃ and 19 ℃ by using the zit1100 5mm nano insulation felt of Nanjing Ziyang New Materials Technology Co., Ltd. under the lining plate near the thick sliding shoes.

Temperature of unused materials

Nano thermal insulation material cylinder

We are very mature in the application technology of thermal insulation of sliding shoe after cement mill. By reducing the temperature of sliding shoe about 8 ℃, we have generally solved the problem of sliding shoe over temperature trip.

It has been successfully applied in pipe mills of cement clinker such as southern cement, Hongshi cement, Jinyu cement, Jidong Cement, conch cement and so on.

The use of nano thermal insulation board meets the needs of capacity expansion, greatly reduces the shell temperature and heat loss. From the above application data and thermal insulation effect, Zit nano thermal insulation material is the preferred new thermal insulation material for various industries in the future, including the cement industry.

Nanjing Ziyang New Material Technology Co., Ltd

官方微信