With the rapid development of China's cement industry, in recent years, cement plants gradually take capacity expansion and energy saving as important measures for the development of cement enterprises. It is understood that in the technical transformation of cement production line, energy saving and consumption reduction, the technical transformation of cement kiln firing system still has more room for improvement. The sintering system of cement kiln has been operating at high temperature for a long time. The original thermal insulation material is calcium silicate board or ceramic fiber board, which has high thermal conductivity. In order to further improve the operation efficiency of cement thermal equipment, a better thermal insulation material is selected to reduce the shell temperature without increasing or even decreasing the thickness of the thermal insulation layer, which can expand the effective volume and reduce the heat loss, so as to reduce energy consumption and improve the economic benefits of the enterprise.

Nanjing Ziyang New Material Technology Co., Ltd. (hereinafter referred to as Nanjing Ziyang) independently developed, produced and sold the zit nano thermal insulation material, which is about 4 times better than the traditional calcium silicate board thermal insulation performance, and can achieve the purpose of expanding the volume and saving energy.

Due to the excellent thermal insulation performance of Nanjing Ziyang nano thermal insulation material, the shell temperature of the equipment can be significantly reduced and more energy can be saved under the same thermal insulation thickness. The following is the performance comparison of various types of nano thermal insulation materials and traditional materials in Nanjing Ziyang. See TABLE-1 for details.

Table 1 main performance indexes of thermal insulation materials

|

Serial number |

Original structure |

Service temperature

|

Density kg / m3 |

compressive strength

|

Reheating line shrinkage 850 ℃ |

thermal conductivity

|

Main chemical composition |

|

1 |

Microporous calcium silicate board |

1000 |

220 |

1.0 |

≤2 |

0.15 |

SiO2 CaO |

|

2 |

950 nano heat insulation board |

950 |

250 |

0.50 |

≤2 |

0.034 |

SiO2 SiC |

|

3 |

1000 type nano heat insulation board |

1000 |

550 |

1.25 |

≤1 |

0.072 |

SiO2 SiC |

|

4 |

1200 type nano heat insulation board |

1200 |

550 |

1.25 |

≤1 |

0.072 |

SiO2 |

|

5 |

Comparison of thermal insulation performance |

25mm950 nano thermal insulation panel is equivalent to 100mm traditional calcium silicate thermal insulation material

|

|||||

1、 2500 ton decomposition furnace of Changde cement of Hunan Zhongcai

It is understood that during the operation of the vertical section of Hunan Sinoma Changde cement calciner, the shell temperature is too high, the average temperature can reach 150 ℃, and the heat insulation effect is very poor, resulting in a large amount of heat loss, reducing the thermal efficiency of the calciner.

Sinoma Changde cement learned that other cement enterprises in the industry used Nanjing Ziyang nano thermal insulation materials in the decomposition furnace, and the thermal insulation application effect was good. After technical exchange with Nanjing Ziyang, Sinoma Changde cement finally decided to carry out thermal insulation application in the vertical section of the decomposition furnace. In the vertical section of precalciner, the 115mm calcium silicate board is replaced by 50mmzit950 nano thermal insulation board, with a service area of 500m² and an expanded effective volume of 32m³, which will be ignited on December 25, 2019.

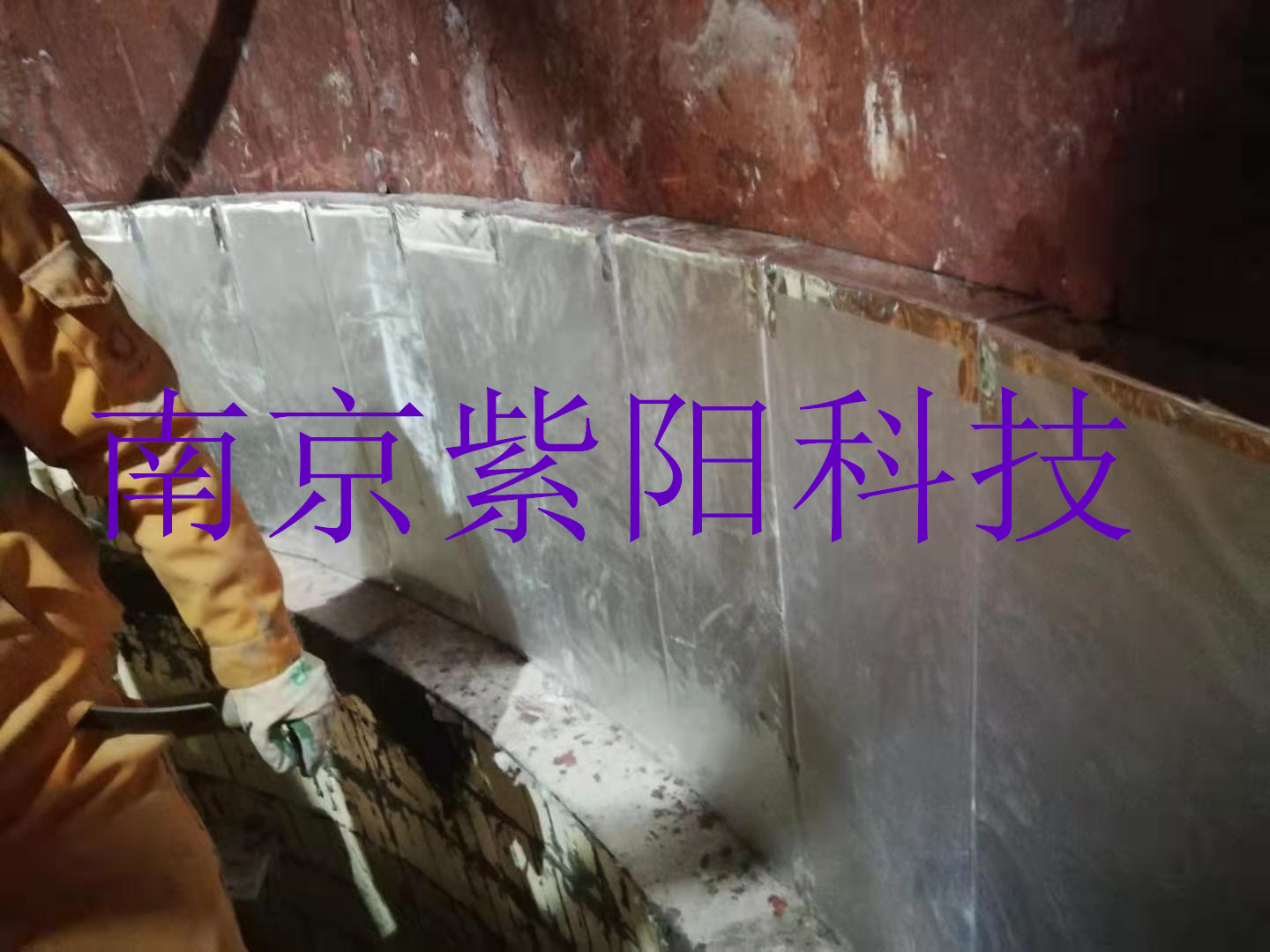

The site construction pictures are as follows:

In order to verify the performance of Nanjing Ziyang zit nano thermal insulation material, Sinoma Changde cement tested the shell temperature after running the calciner for a period of time, and compared with the shell temperature of the original structure. The specific comparison results are shown in the following table-2:

Effect table of thermal insulation transformation of calciner insulation layer-2

|

Serial number |

programme |

Internal temperature |

Shell temperature |

ambient temperature |

Measuring time |

|

1 |

114mm refractory brick + 115mm calcium silicate board |

900℃ |

150℃ |

25℃ |

2019.5.15 |

|

2 |

114mm refractory brick + 115mm calcium silicate board

|

900℃ |

45℃ |

10℃ |

2020.1.13 |

|

3 |

Compared with the original 115mm calcium silicate board, the shell temperature of 50 mm zit950 nano thermal insulation board was reduced by 105 ℃ and the capacity was expanded by 32 m3. |

||||

According to relevant technicians in Ziyang and cement industry in Nanjing, each cubic meter expansion in the decomposition furnace can increase the clinker by 3 tons / day. In this way, the capacity expansion and productivity can be improved while using nano plate in the decomposition furnace, which is also a win-win effect for cement enterprises!

2、 Zhejiang Changxing South Cement 5000 tons C5 level blanking pipe

The shell temperature of C5 blanking pipe of Zhejiang Changxing South Cement Co., Ltd. is too high during operation, and the shell temperature can reach more than 200 ℃. The insulation effect is poor, which leads to a large amount of heat loss and reduces the thermal efficiency.

After the detailed demonstration of Nanjing Ziyang zit nano heat insulation board, Changxing South Cement decided to use 20mmzit950 nano heat insulation board inside the over temperature blanking pipe, which was installed on December 10, 2019. The site installation pictures are as follows:

In order to verify the performance of zit nano thermal insulation material, Changxing South Cement tested the shell temperature after a period of operation of the blanking tube, and compared it with the shell temperature of the original structure. The specific comparison results are shown in the following table-3:

Effect table of heat insulation transformation for insulation layer of C5 blanking pipe-3

|

Serial number |

structure |

Internal temperature |

Shell temperature |

ambient temperature |

remarks |

|

1 |

100 mm castable |

860℃ |

200℃ |

20℃ |

Original plan |

|

2 |

100 mm castable+

|

860℃ |

103.1℃ |

20℃ |

After transformation |

|

3 |

The application of 20mm950 nano heat insulation board can reduce the shell temperature by 96.9 ℃ compared with the original scheme, and the cooling effect is very obvious |

||||

The use of nano thermal insulation board meets the needs of capacity expansion, greatly reduces the shell temperature and heat loss. From the above application data and thermal insulation effect, Nanjing Ziyang nano thermal insulation material is the preferred new thermal insulation material for all walks of life in the future, including the cement industry.

After the Spring Festival in 2020, Nanjing Ziyang nano plate will be installed in Henan Jinrong cement kiln head cover and denitration chamber, Guangling Jinyu cement blanking pipe, Guilin Southern Cement grate cooler, calciner and tertiary air pipe, Guangxi Jinli cement kiln head cover and calciner, xingchuancheng Jianbao cement tertiary air pipe and Jiangxi Hongshi Yingpeng cement mill, How to wait for the high temperature in summer? Please look forward to the field test!

Nanjing Ziyang New Material Technology Co., Ltd

官方微信