In the face of both the epidemic situation and the impact of the market, reducing production costs, improving economic benefits and enhancing survival ability are the main breakthrough points to survive the cold winter. How to improve the working efficiency of cement equipment, improve the production efficiency of cement enterprises and reduce production costs has become a problem to be solved by more and more cement enterprises, and also a research course for many cement equipment enterprises.

In view of the actual situation of increasing production and reducing consumption of domestic cement enterprises, the microcrystalline ceramic materials independently developed by Nanjing Ziyang New Material Technology Co., Ltd. (hereinafter referred to as "Nanjing Ziyang") provide feasible solutions to solve the clinker skinning phenomenon in flue gas chamber, discharge pipe, decomposing furnace vertebral body and other parts. The installation and application of microcrystalline ceramic materials provide convenient conditions for cement sintering system to reduce clinker scaling, material deposition, operation cost and production efficiency.

The zit nano thermal insulation material independently developed, produced and sold by Nanjing Ziyang is about four times better than the traditional calcium silicate board in thermal insulation performance, which can achieve the effect of increasing production and improving efficiency by expanding the internal volume, reducing the shell temperature and reducing energy consumption in the cement kiln firing system.

Compared with the super thermal insulation performance of zit nano thermal insulation material, the shell temperature of the equipment can be significantly reduced and more energy can be saved under the condition of the same thermal insulation thickness. The following is the performance comparison of various types of nano thermal insulation materials and traditional thermal insulation materials in Nanjing Ziyang Table 1 and the construction pictures of various companies.

Comparison of main performance indexes of thermal insulation Materials-1

|

Serial number |

Original structure |

Service temperature

|

densityKg/m3 |

Compressive strength Mpa |

Shrinkage of heavy firing line 850 ℃ |

thermal conductivity

|

chemical composition |

|

1 |

Microporous calcium silicate board |

1000 |

220 |

1.0 |

≤2 |

0.15 |

SiO2 CaO |

|

2 |

950 nano heat insulation board |

950 |

250 |

0.50 |

≤2 |

0.034 |

SiO2 SiC |

|

3 |

1000 type nano heat insulation board |

1000 |

550 |

1.25 |

≤1 |

0.072 |

SiO2 |

|

4 |

1200 type nano heat insulation board |

1200 |

550 |

1.25 |

≤1 |

0.072 |

SiO2 |

|

5 |

Comparison of thermal insulation performance |

25mm950 nano thermal insulation panel is equivalent to 100mm traditional calcium silicate thermal insulation material 50mm1000 (or 1200) nanoplate is equivalent to 100mm traditional calcium silicate thermal insulation material |

|||||

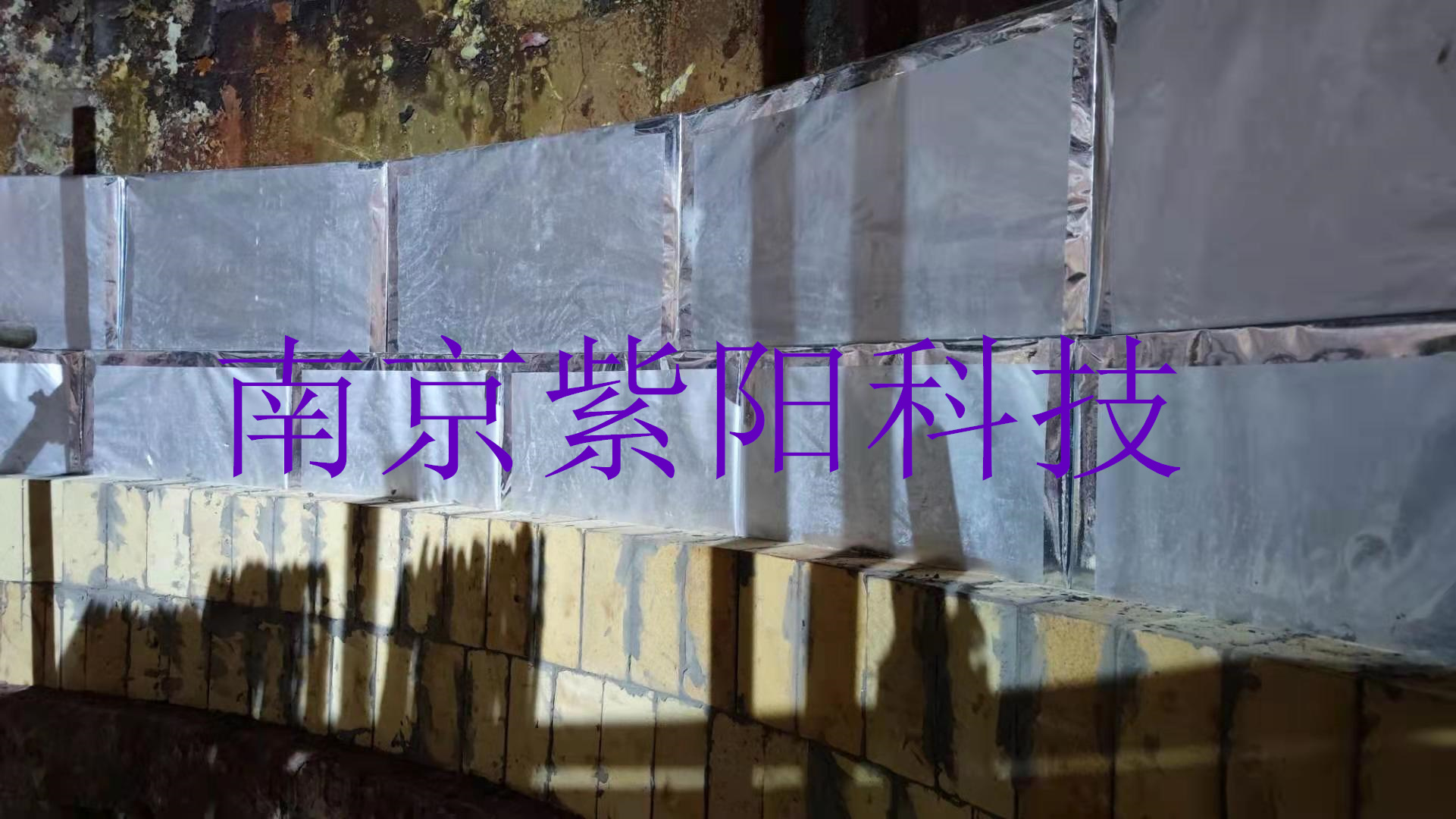

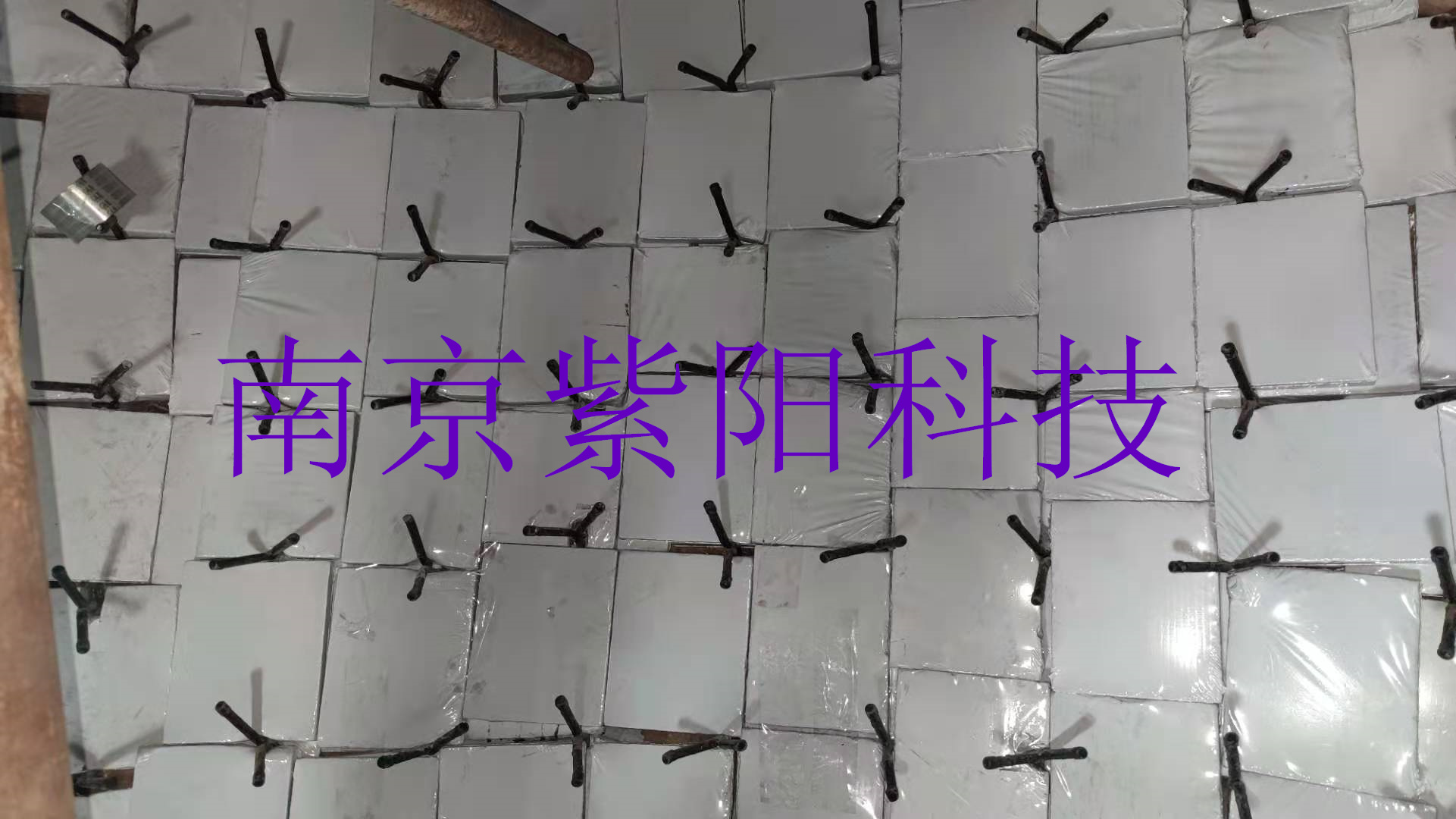

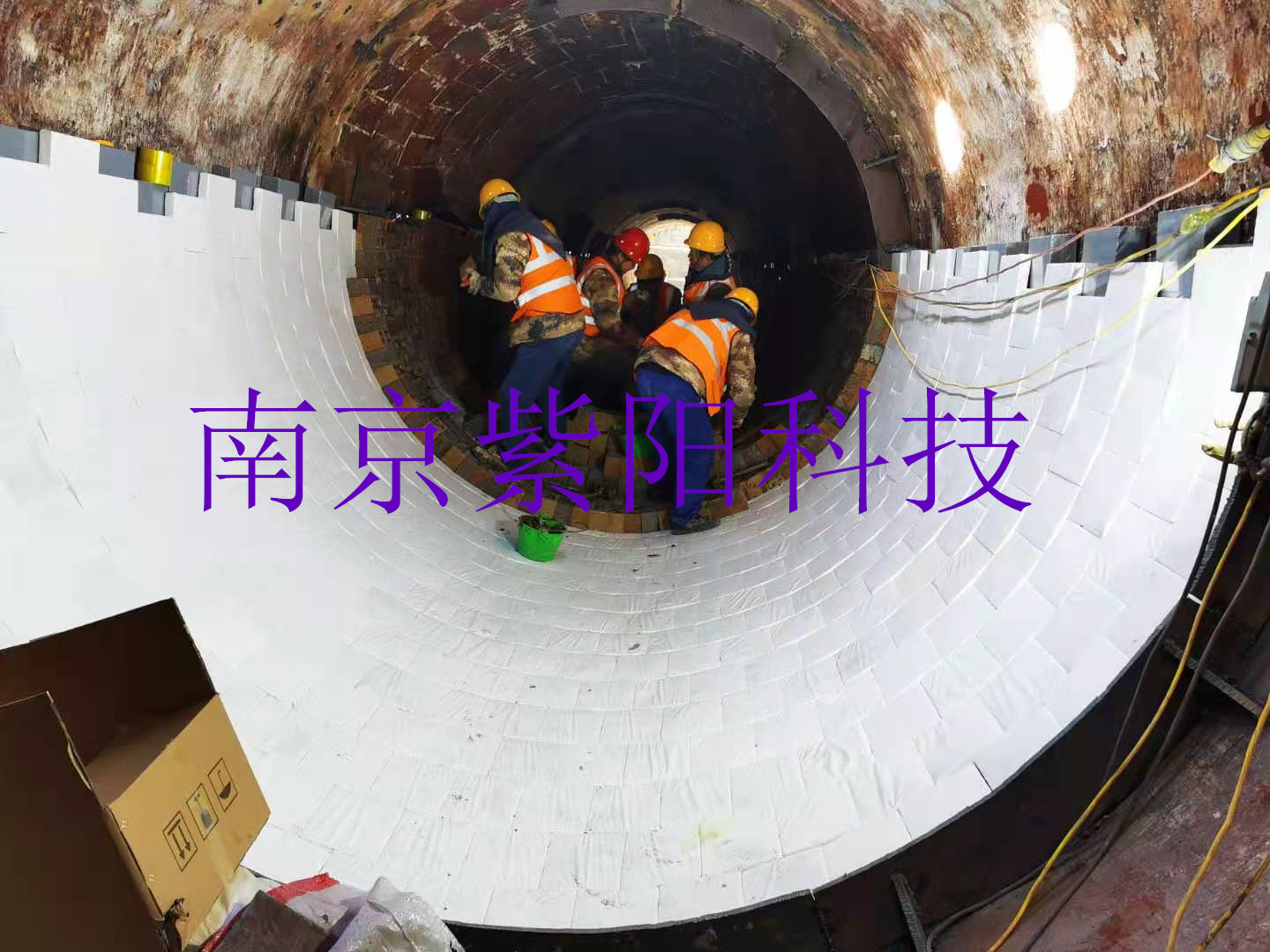

1、 Site construction pictures of zit microcrystalline ceramic board

1. Installation picture of microcrystalline board in flue gas chamber of Liupanshui Haolong Cement Co., Ltd

2. installation picture of the tremie tube of xingchuancheng Ruixing Cement Co., Ltd

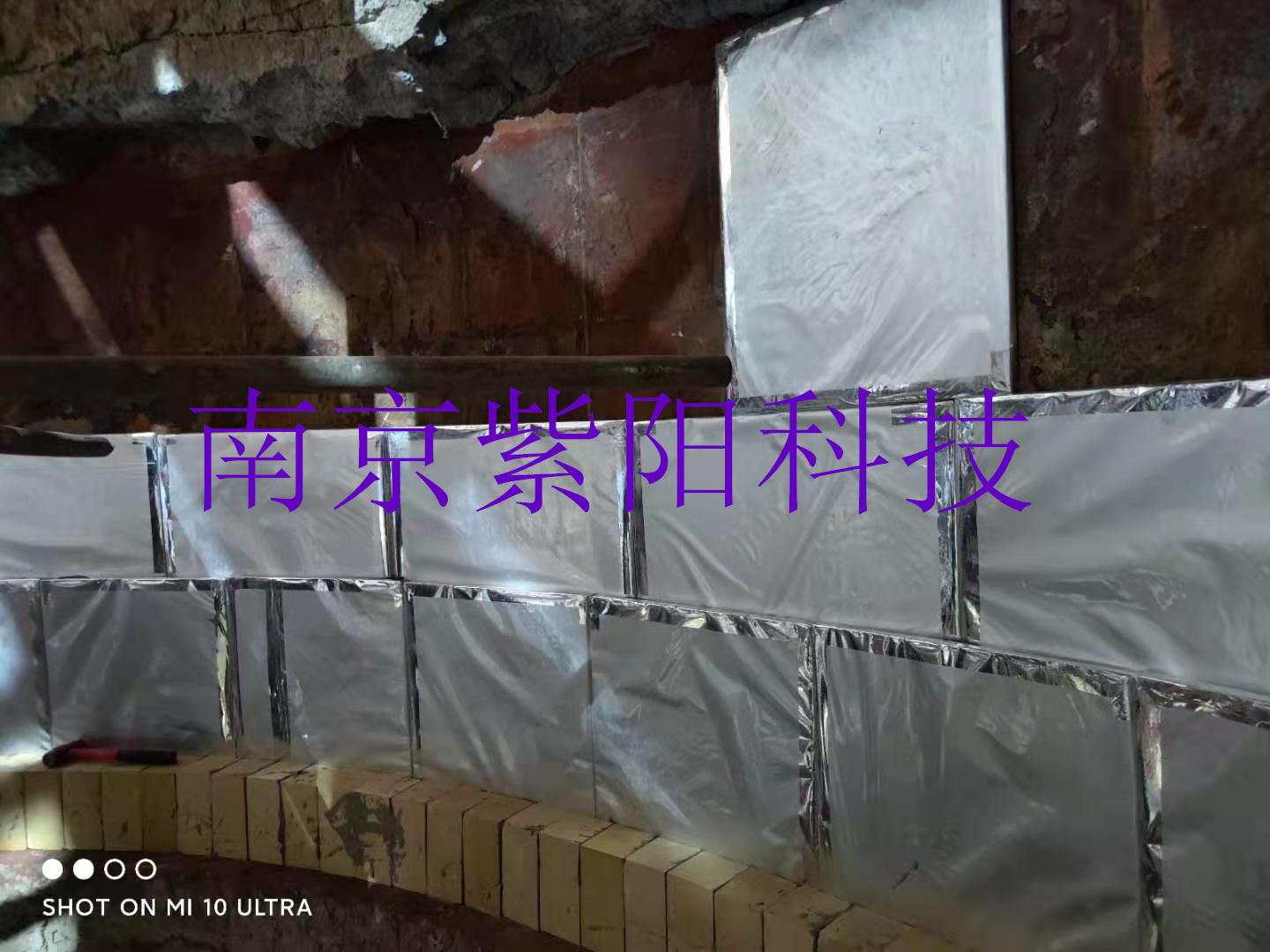

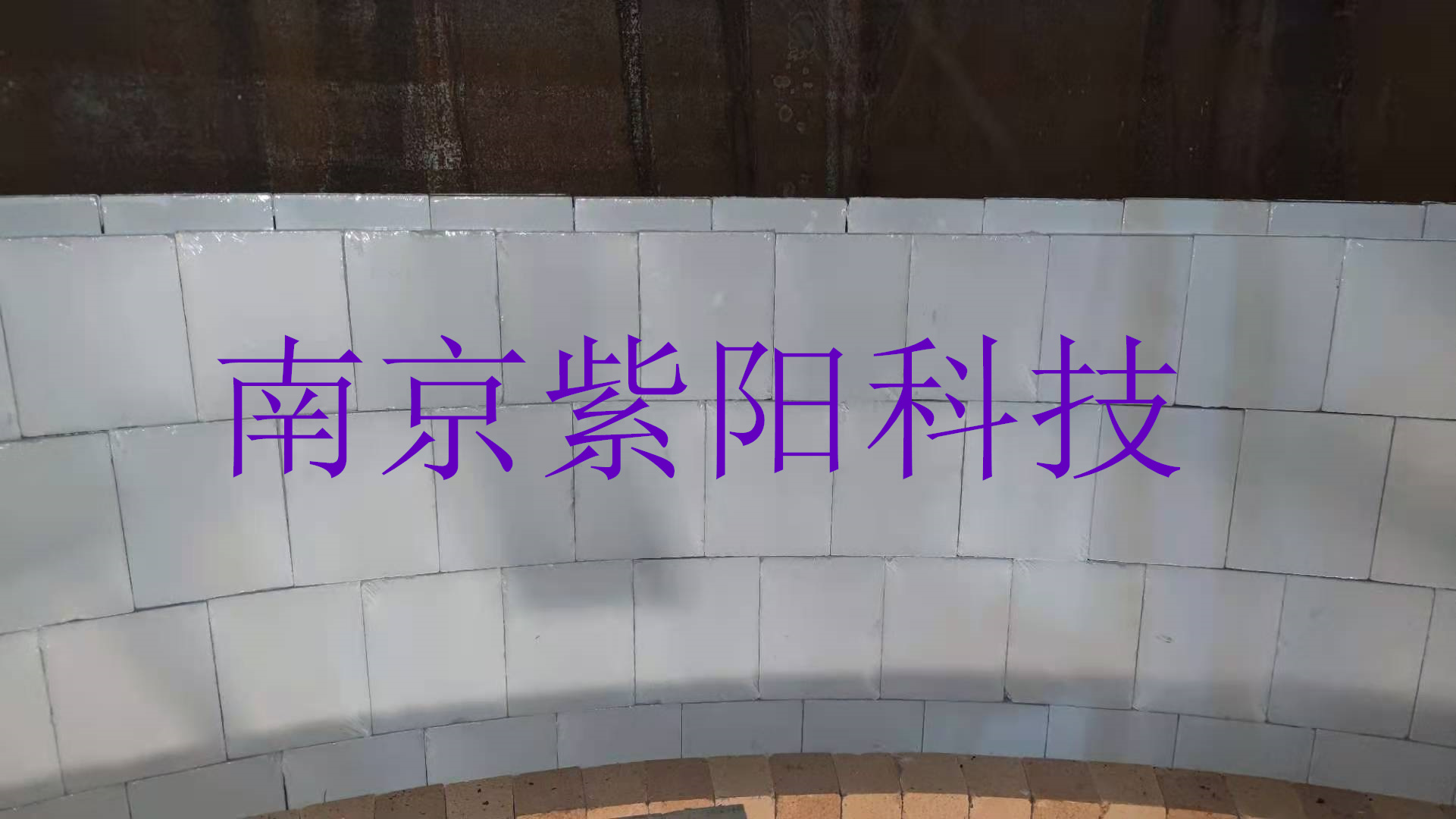

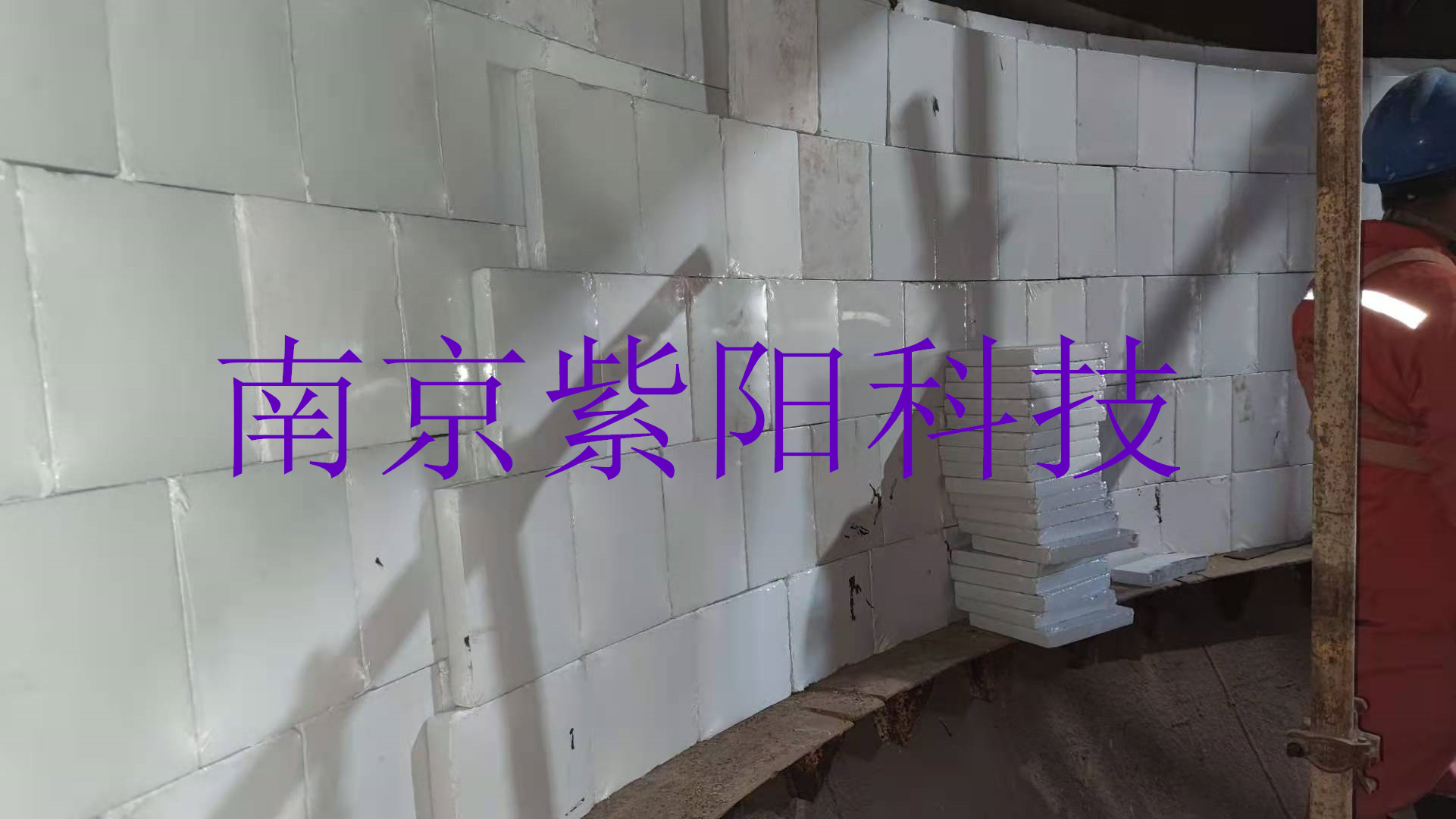

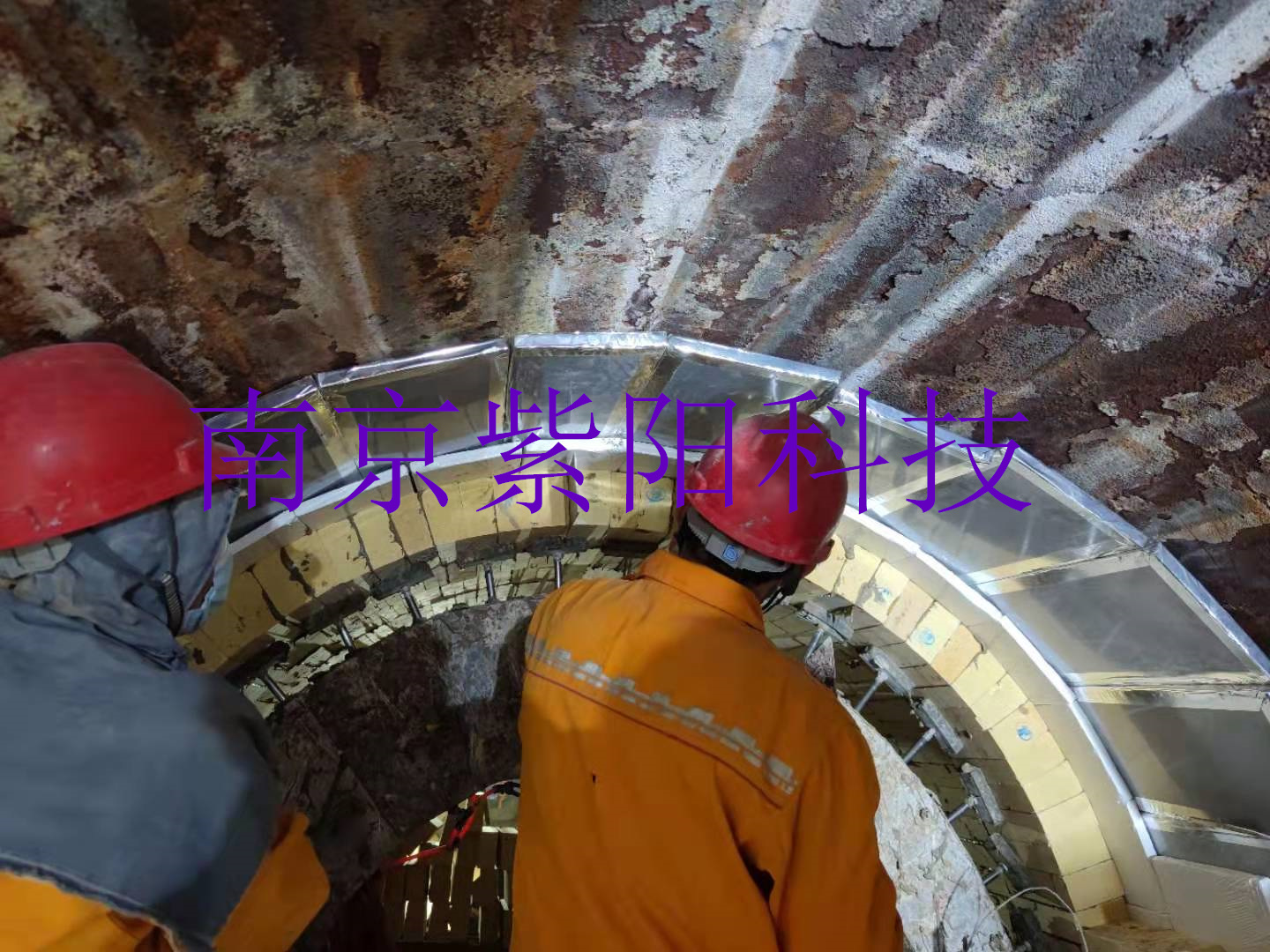

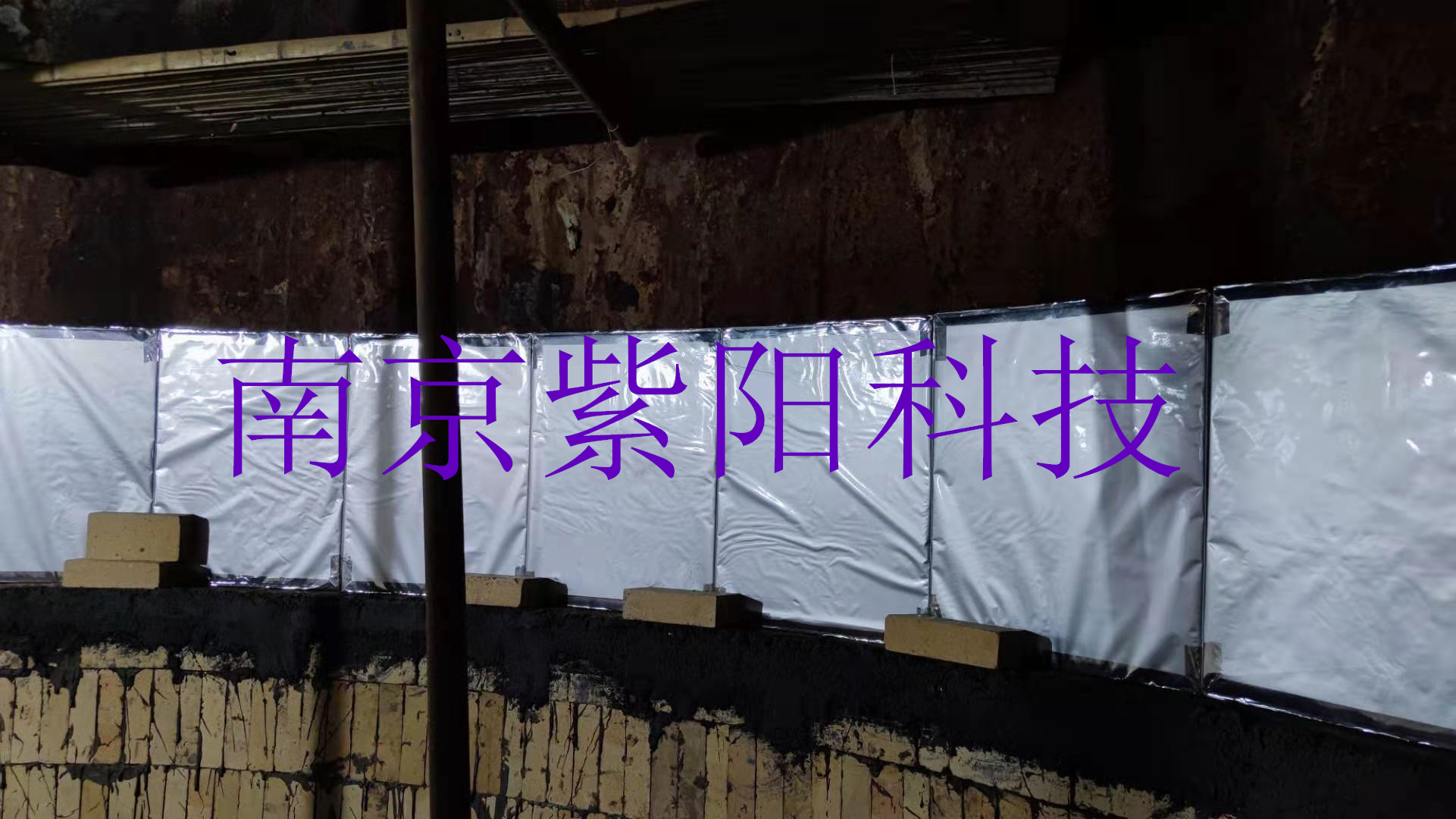

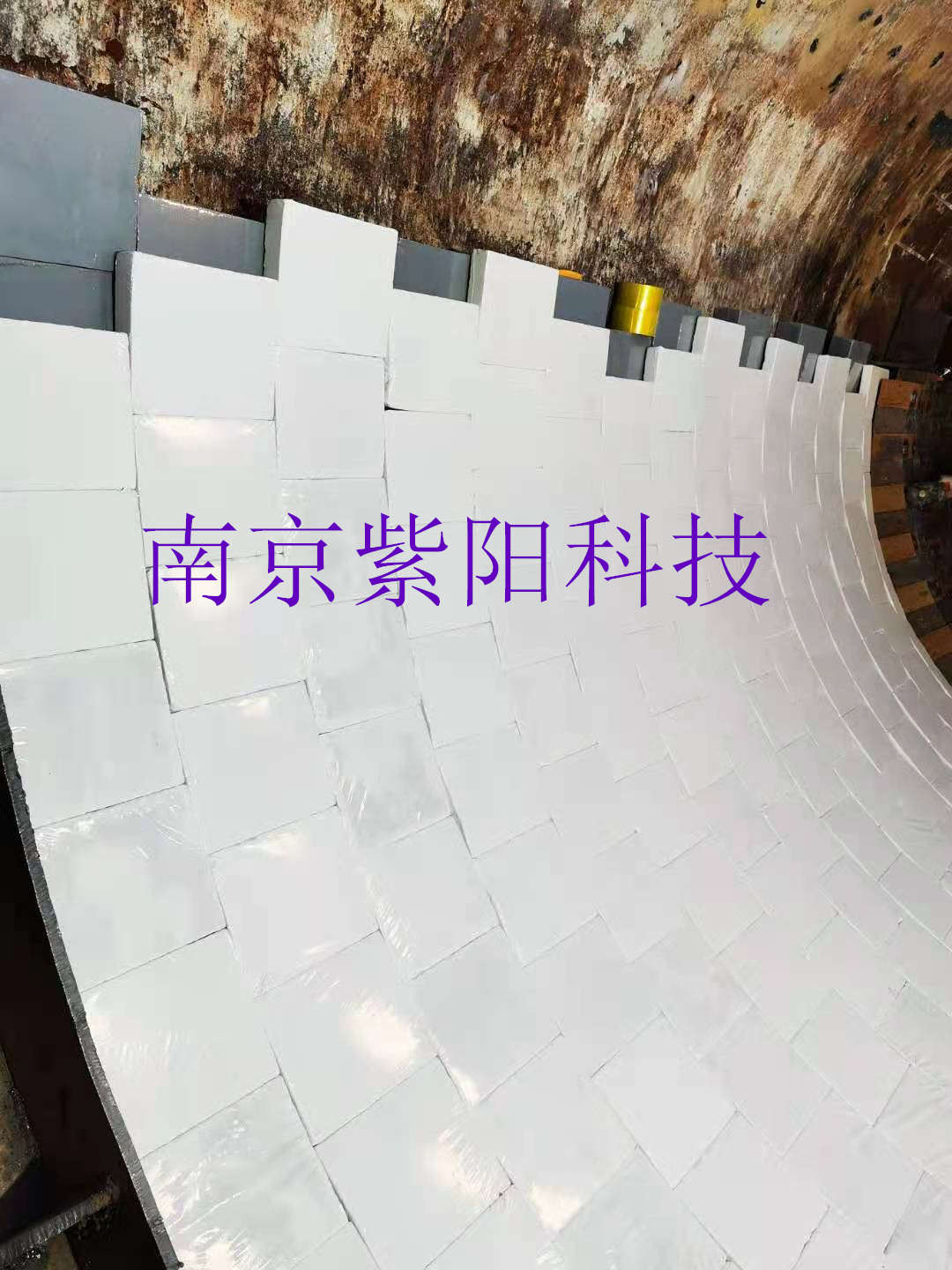

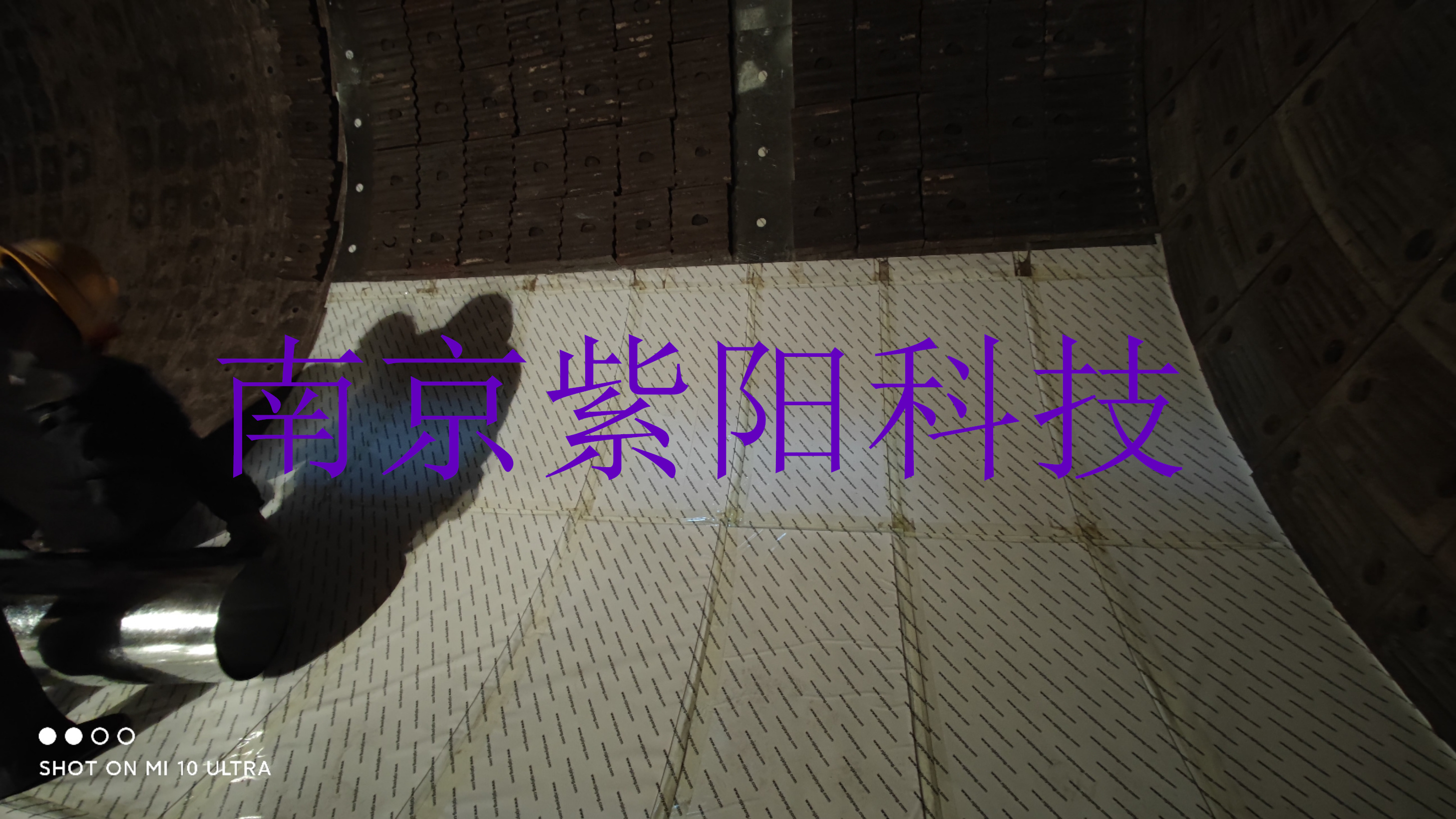

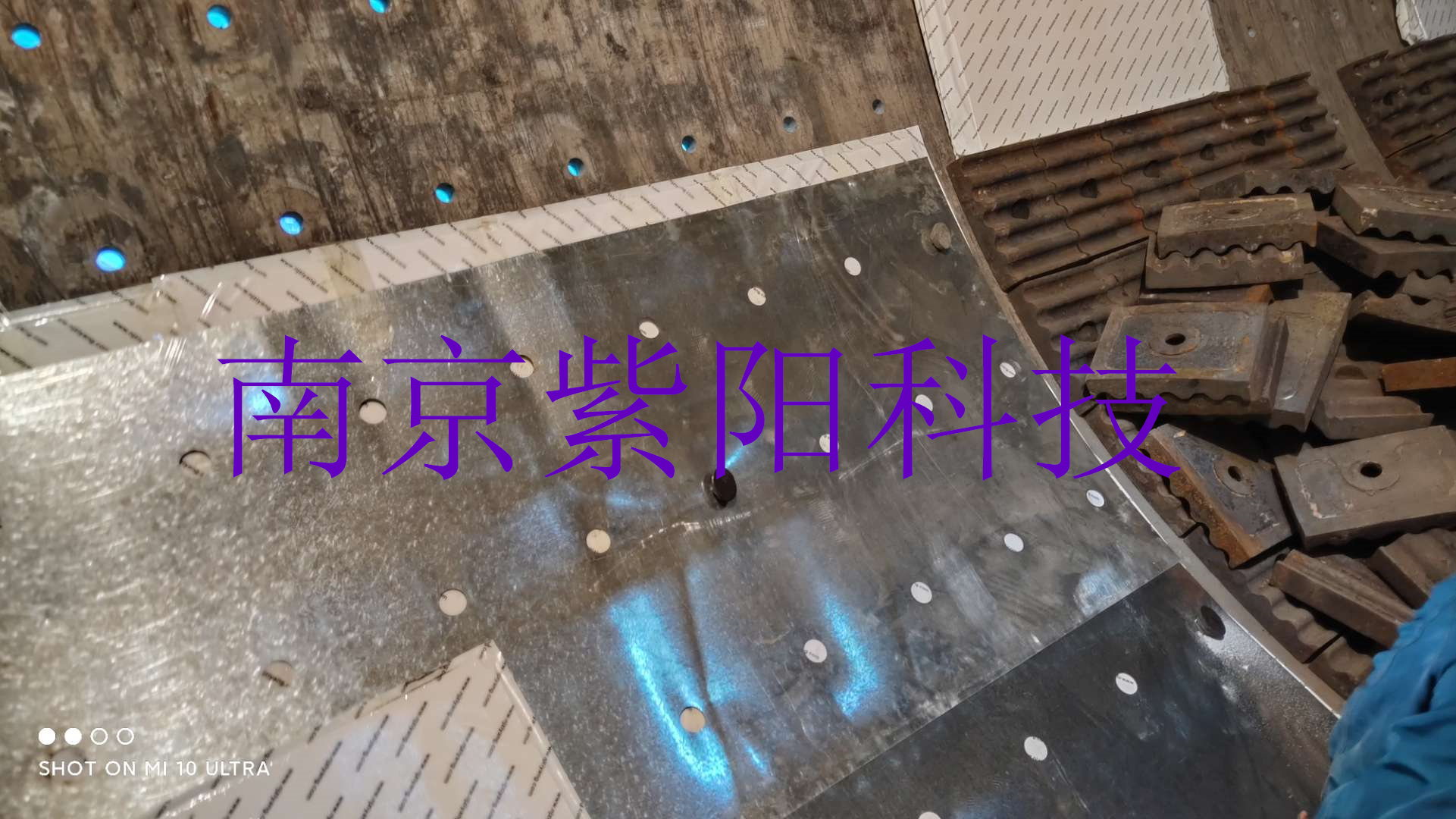

2、 Site construction pictures of zit nano thermal insulation material

1. Installation picture of nano plate for 3200t calciner of Ningxia Yinghai Tianxiang building materials Co., Ltd

2. picture of 6000 ton nano plate construction of Qinglong Panjiang Cement Co., Ltd

3. Construction picture of nano plate for 2500 ton calciner of xingchuancheng Xichang Aerospace Cement Co., Ltd

Construction picture of 2500 ton cyclone nano plate of Xichang space Cement Co., Ltd

4. Installation picture of 2500t tertiary air duct nano plate of Sinoma Changde Cement Co., Ltd

5. construction picture of 5000 ton decomposition furnace nanoplate of Guizhou Guizhou guijinzhou building materials Co., Ltd

6. Construction picture of 2500 tons calciner nano plate of Dafang Yonggui building materials Co., Ltd

7. Installation picture of 5000t tertiary air duct nano plate of Henan Jinrong Cement Co., Ltd

8. Installation picture of cement slipper insulation felt of Puyang Tongli Cement Co., Ltd

The above are some recent installation and application cases of microcrystalline materials and nano materials of our company. Compared with the previous cement customers, the material properties, guidance services and technical support of Nanjing Ziyang have been flying over! On the basis of ensuring the existing, Nanjing Ziyang also constantly innovate and improve! Keep going, can we go further! Hard innovation, will develop better!

Nanjing Ziyang New Material Technology Co., Ltd

官方微信